Plastic Bottle Granulator

- Meenchi

- China

- About 40 working days after deposit

- 5 sets per month

The waste pet bottle recycling granulator is a twin-screw extruder, which has excellent mixing performance, good self-cleaning type and flexible modular combination characteristics.

The pet pelletizer machine does not need complex pre crystallization drying system, and can achieve ideal pet viscosity control, with small IV drop, and can achieve viscosity increase by adding appropriate additives

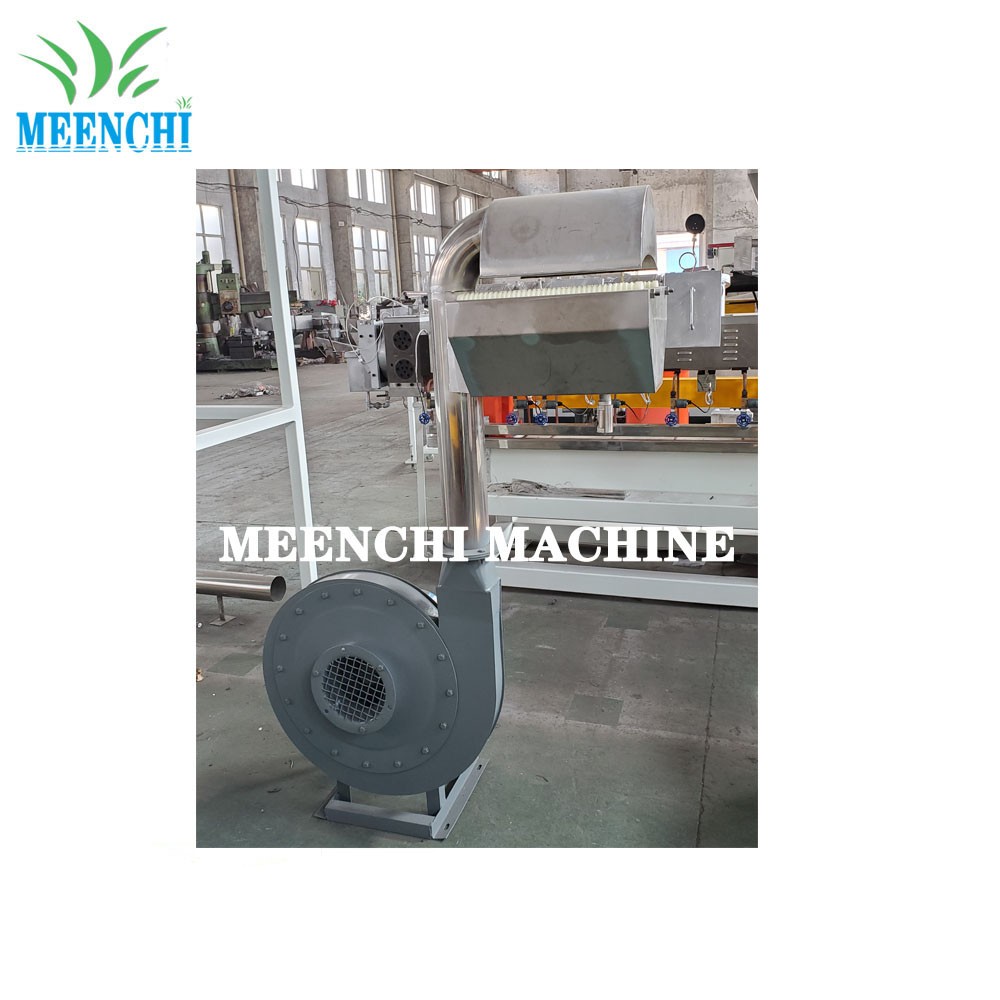

PLASTIC BOTTLE GRANULATOR

PRODUCT DESCRIPTION:

Pet granulator is used in the field of pet waste flake granulation. Through extrusion, cutting, drying and other processes, waste bottles are made into pellets, which are widely used in sheet, profile, plastic broom, plastic bottle and other plastic industries.

From the feeding system to the final product, we can design and develop a complete system to meet all your production requirements. We have not only pet waste bottle granulation line, but also HDPE bottle granulation line.

We will provide you with a granulation system with good quality and price according to your requirements.

PRODUCT ADVANTAGES:

1. Highly efficent: the machine is automatic and with less power consumption.

2. Special screw design: We will design the screw up to customer different material and the material of screw and barrel can be 38CrMoAL or bimetallic.

3. This machine can carry out ideal viscosity of PET without complicated precystallization dryer system. Only a bit IV will be reduced. It can improve IV in the condition of adding some suitable additive.

5. Pet granulator control cabinet: many famous brands of electrical components, such as abb, Siemens, Schneider, Delixi, delta Omron, RKC, etc., with reliable and guaranteed quality! Optional PLC touch screen control panel

6. Pet bottle pelletizing machine use twin screw design and hdpe pe pp etc material bottle use single screw type .

PRODUCT PARAMETERS:

Model | TSSK20 | TSSK30 | TSSK35 | TSSK50 | TSSK65 | TSSK72 | TSSK92 |

Screw diameter(mm) | 21.7 | 30 | 35.6 | 50.5 | 62.4 | 71.2 | 91 |

| Rotary speed(rpm) | 600 | 400 | 400/600 | 500/600 | 400/500 | 400/500 | 400/500 |

| Main motor power(kw) | 4 | 11 | 11/15 | 37/45 | 55/75 | 90/110 | 220/250 |

L/D | 32-40 | 28-48 | 32-48 | 32-48 | 32-48 | 32-48 | 32-40 |

Capacity(kg/h) | 2-10 | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 600-1000 |

OUR CUSTOMER VISIT OUR FACTORY:

PHOTO OF FINAL PRODUCTION: