Ocean Sea Ball Blow Moulding Machine

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

The company improves work efficiency with scientific production process and advanced equipment, reduces labor intensity of workers, saves energy, and greatly reduces production cost. Therefore, it provides customers with a variety of production equipment with high quality and low price. We have a large number of customers who come to our company to purchase equipment, and the production workshop needs to sell with efficient operation.

The company has an efficient and professional after-sales service team. No matter what problems appear in the equipment, it can communicate and solve them in time, so as to guarantee the long-term development and sustainable profitability of customers.

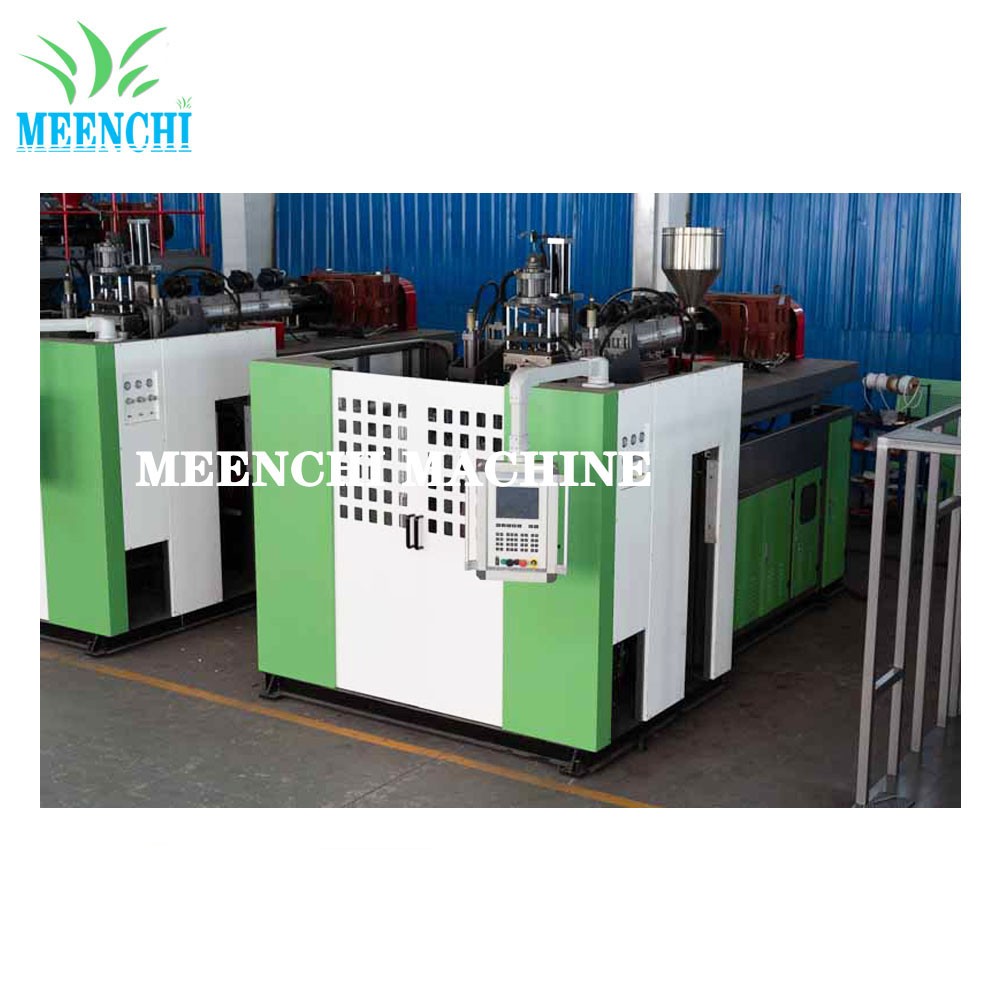

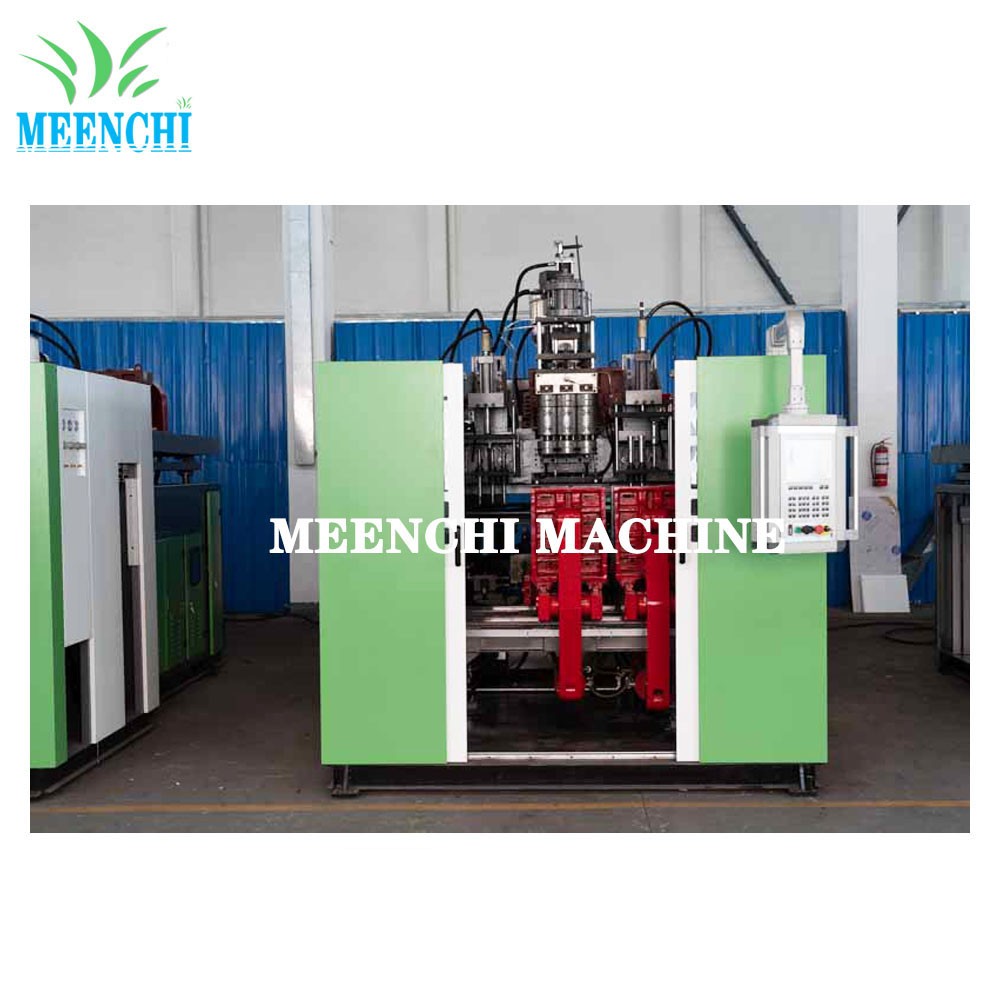

OCEAN SEA BALL BLOW MOULDING MACHINE

PRODUCT DESCRIPTION:

Blow molding, also known as hollow blow molding, is a rapidly developing plastic processing method. The tubular plastic parison obtained by extrusion or injection molding of thermoplastic resin is placed in the split mold when it is hot (or heated to the softened state), and compressed air is introduced into the parison immediately after the mold is closed, so that the plastic parison is blown and pressed against the inner wall of the mold, and various hollow products are obtained after cooling and demoulding.

Ocean ball is the product of baby playground, mischievous castle and outdoor activity supplies, etc., which can bring wisdom and fun to babies.

The ocean ball adopts the technology of two-step forming and no hole blow molding. The ocean ball (Bobo ball) has pores, but the pores are all in the mold! The pore distribution is very small!

At present, 6cm and 8cm diameter ocean balls are sold best . If you need other sizes of ocean balls, our machine can produce customized sizes of ocean balls for you.

PRODUCT ADVANTAGES:

1: Plasticizing system: high efficiency plasticizing mixing screw ensures full and even plastic plasticizing.

2: Hydraulic system: double proportional control, swing frame adopts linear guide rail and mechanical decompression, running more stable and high-speed, equipped with imported famous hydraulic components, stable and reliable.

3: Extrusion system: frequency control + hard tooth reducer, stable speed control, low noise, durable.

4: Control system: This machine is controlled by PLC human-machine interface (Chinese or English), and operated by touch-screen operation. The functions of process setting, change, retrieval, monitoring, fault diagnosis, etc. can be realized on touch-screen. Easy to operate.

5: Opening and closing mold system: beam arm, three-point position, central mold locking mechanism, mold locking force balance, no deformation, high precision, less resistance, fast and so on.

PRODUCT PARAMETERS:

| SPECIFICATIONS & TECHNICAL DATA | ||||

Extrusion Unit | Screw Diameter | mm | 70 | 90 |

| Plasticizing Capacity | Kg/hour | 100 | 140 | |

| Temperature Control Zone | Zone | 4 | 4 | |

Continuous Head | Screw Diameter | mm | 75 | 90 |

| Double Head Central Distance | mm | 160 | 180 | |

| Triple Head Central Distance | mm | 200 | 260 | |

| Four Head Central Distance | mm | 420 | 600 | |

| Clamping Unit | Clamping Force | KN | 120 | 120 |

| Platen Size | mm | 540*520 | 520*540 | |

| Platen Distance | mm | 280-660 | 280-660 | |

| Moving Distance | mm | 620 | 620 | |

| Max Mould Size | mm | 520*540 | 520*540 | |

Driving System | Extrusion Motor Power | KW | 30 | 37 |

| Pump Motor Power | KW | 11 | 15 | |

| Machine Total Power | KW | 67.7 | 82.1 | |

| Average Power Consumption | KW | 28.5 | 36.4 | |

PRODUCT DETAILS: