Packaging Shredder

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

With the popularization of global urbanization, the acceleration of the pace of life and the increase of domestic garbage, it has become a very serious environmental problem in China and even in the whole world.

It is estimated that the growth rate of garbage in developed countries is 3.2% - 4.5% and that in developing countries is 2% - 3%. The annual output of garbage in the world is 10 billion tons. The growth rate of urban garbage in China is about 9%, and the annual output of garbage is about 150 million tons.

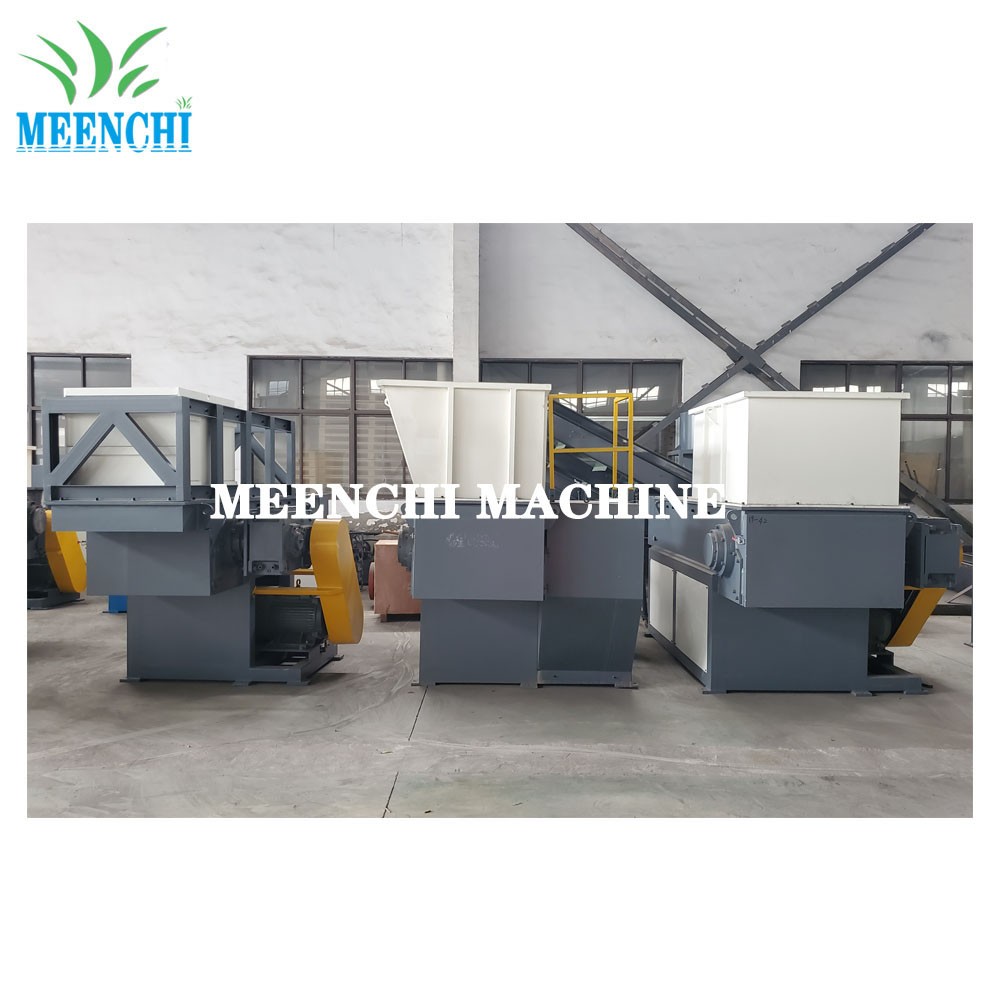

Plastic recycling shredder of our company can tear all kinds of packaging materials in our life, such as plastic buckets,Chemical buckets, blue buckets, IBC buckets, metal buckets, wooden pallets, PP woven bags, various packaging films.

PACKAGING SHREDDER

PRODUCT DESCRIPTION:

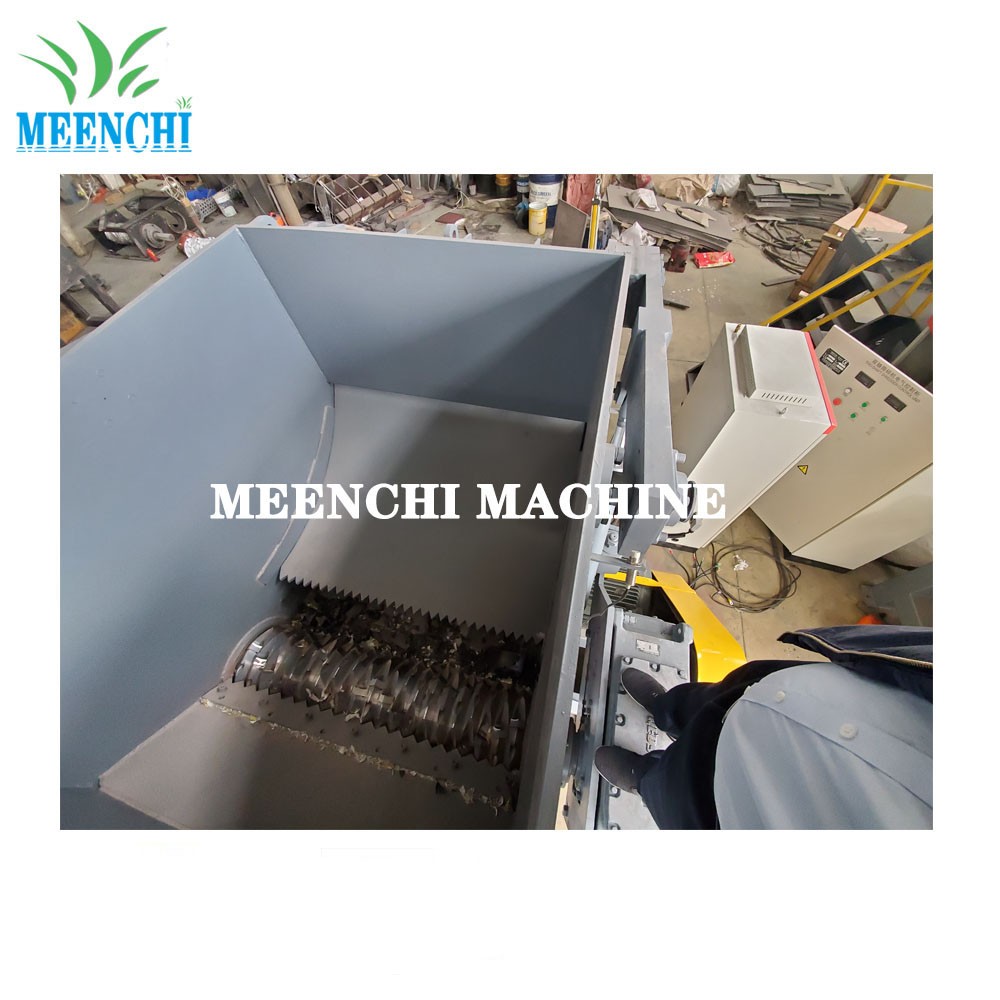

The plastic scrap shredder processes the plastic according to the shearing principle. The machine drives the main shaft to rotate at a high speed through the belt pulley connected with the main shaft. During the rotation process, the main shaft is fixed on the rotor blade and the blade fixed on the body to form the shearing port. After entering the machine cavity through the feeding port, the material is initially chopped through the continuous change of the shearing port. After being chopped The materials that meet the size requirements are directly discharged out of the machine cavity through the screen, and the larger materials are turned up again under the effect of the internal air flow into the shear port for crushing until the size meets the crushing requirements.

Due to the emergence of a lot of packaging waste in people's lives, our company has developed a lot of packaging shredders:plastic pellet grinder、cartoon shredder machine、corrugated box shredder、drum shredder machine、plastic can crusher、plastic container shredder、wood pallet shredder、woven bag shredder and etc packing shredder machine.

EIGHT ELEMENTS OF DAILY MAINTENANCE OF PLASTIC SHREDDER:

1. The machine should be well grounded.

2. Add lubricating oil to the bearing regularly to ensure the lubrication between the bearings, such as adding grease or molybdenum disulfide, etc.

3. The heavy duty plastic shredder shall be placed in the ventilation position to ensure the heat emission of the motor and extend its service life.

4. Regularly check whether the belt of plastic crusher is loose and adjust it in time.

5. Check the tool screws regularly. After using the new plastic crusher for 1 hour, fasten the screws of the moving tool and the fixed tool with tools to strengthen the fixity between the blade and the tool holder.

6. In order to ensure the sharpness of the cutter cut, it is necessary to check the cutter frequently to ensure its sharpness and reduce unnecessary damage to other parts caused by blunt blade.

7. When replacing the cutter, the clearance between the moving cutter and the fixed cutter: 0.8mm for the crusher above 20HP is better, and 0.5mm for the crusher below 20HP is better. The thinner the recycled material is, the larger the gap can be properly adjusted.

8.Before the second start-up, the remaining debris in the machine room shall be removed to reduce the start-up resistance. The inertia cover and pulley cover shall be opened regularly, and the ash outlet under the flange plate shall be removed, because the powder discharged from the plastic crusher chamber enters the shaft bearing.

PRODUCT PARAMETERS:

| Model | MC-600 | MC-800 | MC-1000 | MC-1300 | MC-1500 |

| Motor Power(kw) | 22 | 37-45 | 55 | 75 | 90 |

| Rotary Blades(pcs) | 26 | 46 | 56 | 72 | 86 |

| Capacity (kg/h) | 250-300 | 400-600 | 600-1000 | 800-1300 | 1000-1500 |

PRODUCT DETAILS:

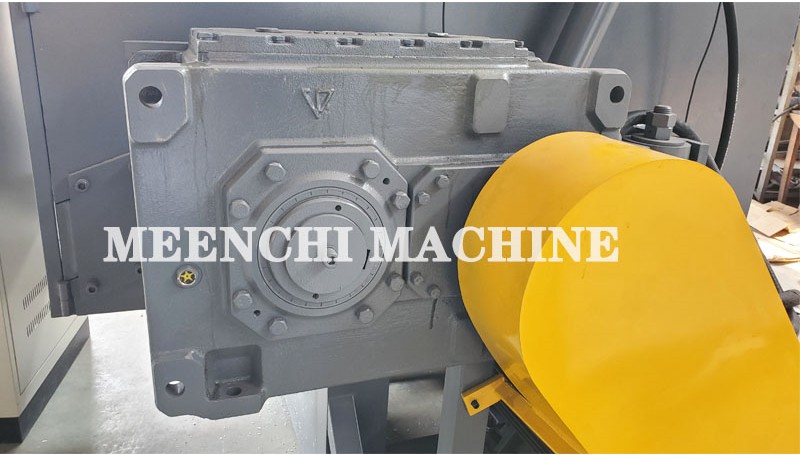

Gear box

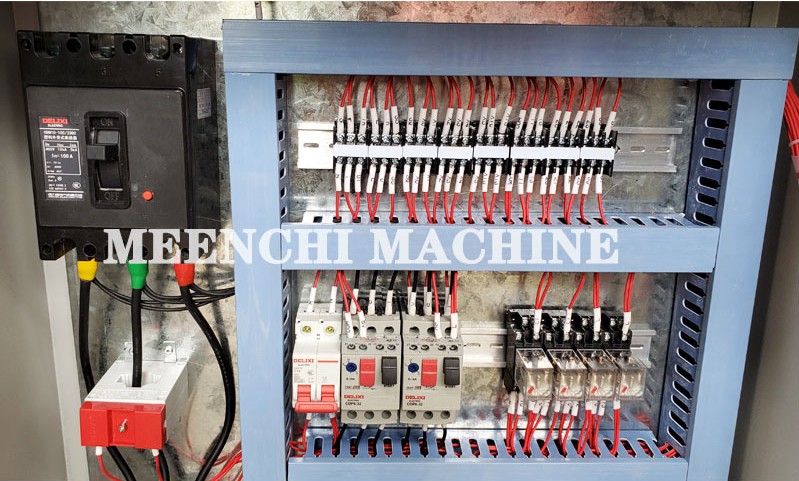

Electric appliance