Plastic Film Granulator Machine

- Meenchi

- China

- About 40 working days after deposit

- 5 sets per month

Waste plastic film pellet making machine is very easy to recycle waste plastic (waste film, plastic bag, woven bag, washed agricultural film, plastic film, greenhouse film and other waste plastic). It is suitable for recycling and pelletizing of all kinds of waste plastic. Output: 100-1000kg / h.

This pelletizing equipment can be matched with pp pe film washing line and film squeezer granulation machine at the same time. We are specialized in making machines, which can be customized according to customers' raw materials and requirements.

PLASTIC FILM GRANULATOR MACHINE

PRODUCT DESCRIPTION:

1. Plastic pelletizing equipment is special equipment for the PE PP film recycling granulating, it equipped with comacting machine which cound pre- compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity and save labour cost.

2. Plastic recycling granulator has two vacuum exhuasting mouth on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

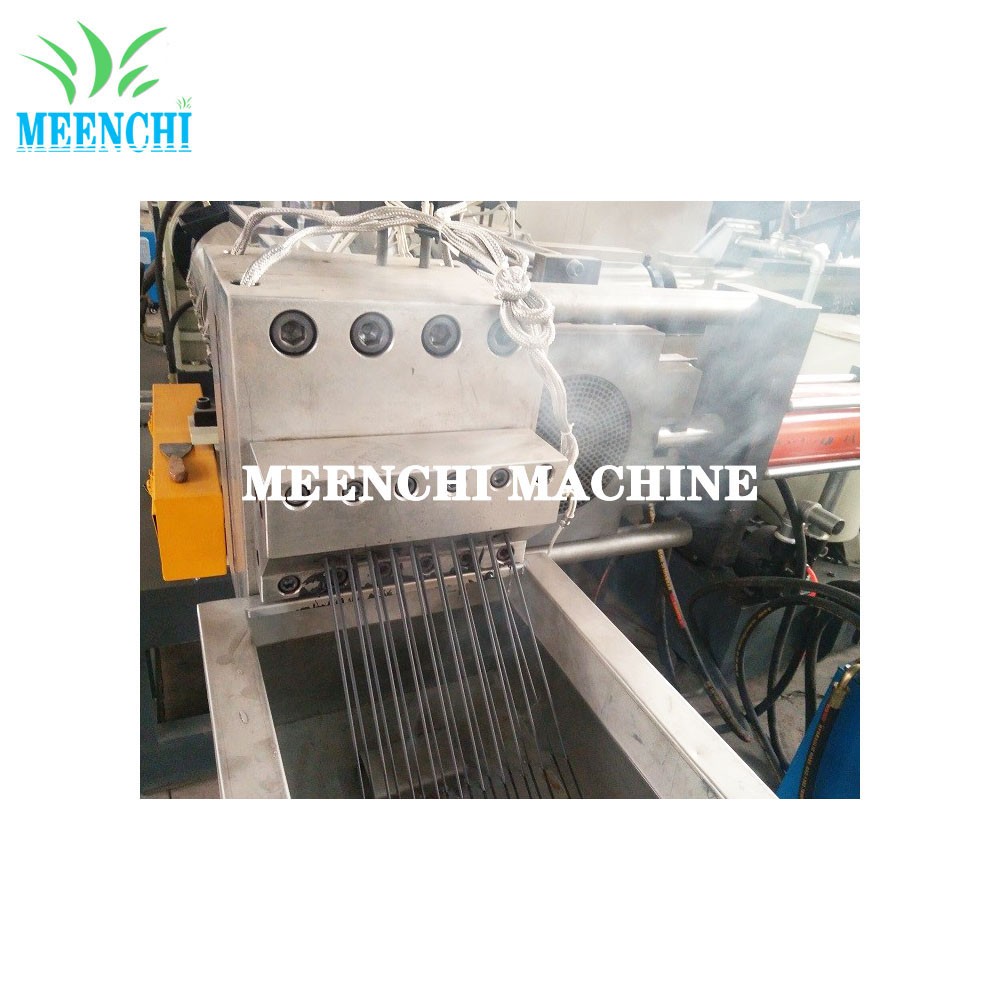

3. At the end of screw barrel, it equipped with double post fast speed hydraulic non -stop screen changer which can effetively filt out the dirty in the plastic melt.

4. The pelletizing machine plastic adopts water flush pelletizing which is easier to operate, and the shape and appearance of granule is good.

PRODUCTION FEATURES:

1. Film granulator can make PP, PE, BOPP, LDPE, LLDPE, HDPE, PA, PETand other films into particles. Then customers can use these particles to blow film or put them into injection molding machine2. Final product: plastic granules.

3. This pellet extruder machine has low energy consumption, stable output, low noise and high automation.

4. The pelletizing equipment can make the output from 100 to 1000kg/h.

5. The plastic film granulator machine has two type: strip type and watering type.

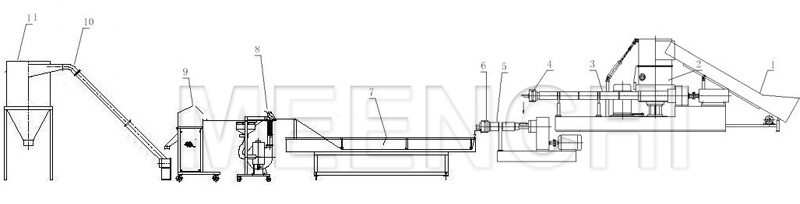

WORKING FLOW:

Conveying feeding → Metal detector → Film Agglomerator /Compactor → 1# Degassing screw extruder → 1# Hydraulic filer exchanger → 2# screw extruder → 2# Hydraulic filer exchanger → Mould head → water ring cutting → Dewatering machine→ Air dryer Blowing system → Storage hopper → Finished product packing.

TECHNICAL PARAMETER:

| TECHNICAL OF PLASTIC GRANULATING MACHINE | ||||

| Model of plastic granulator machine | SJ85 | SJ100 | SJ130 | SJ160 |

| extruder screw diameter (mm) | 85 | 100 | 130 | 160 |

| main motor of extruder (kw) | 55 | 90 | 132 | 160 |

| main motor of compacting machine(kw) | 37 | 55 | 75 | 90 |

| production capacity (kg/h) | 100-150 | 200-300 | 300-400 | 500-600 |

PRODUCT CONTRAST CHART: