Plastic Granulator Machine

- Meenchi

- China

- About 40 working days after deposit

- 5 sets per month

Plastic pelletizer is also known as plastic granulator, one of the plastic extrusion molding equipment. It is a machine that heats the plastic raw materials to a viscous flow state.

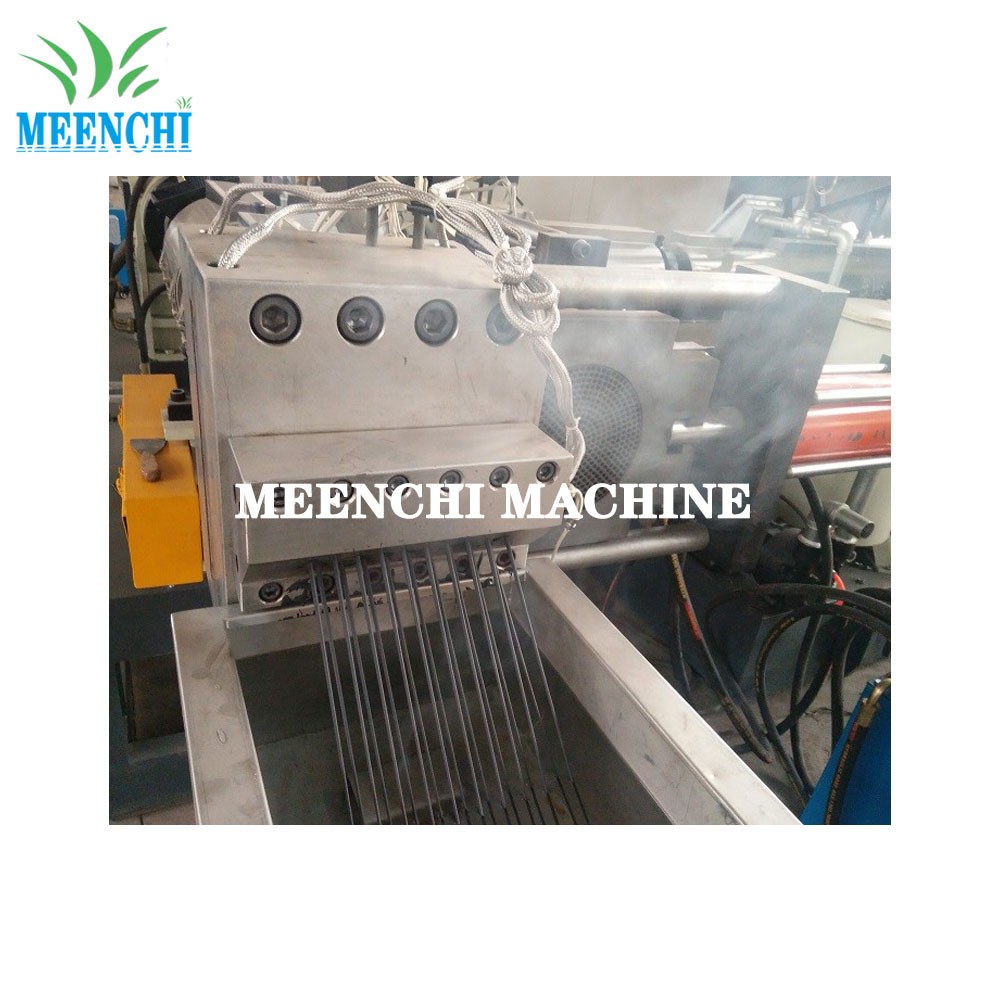

Under the action of pressure, the plastic raw materials are extruded continuously through the extrusion die head, and then cooled to a strip glass state. Through the pelletizing device, round columnar or elliptical plastic particles are obtained.

Plastic granulating machine is mainly used for processing waste plastic film (industrial packaging film, agricultural mulch film, greenhouse film, beer bag, handbag, etc.), woven bag, agricultural convenience bag, basin, barrel, beverage bottle, furniture, daily necessities, etc., which is applicable to most common waste plastics.

PLastic granulator machine is the most widely used, most widely used and most popular plastic recycling processing machinery in the waste plastic recycling industry

PLASTIC GRANULATOR MACHINE

PRODUCT DESCRIPTION:

And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

PRODUCT ADVANTAGES:

1. Allow free assembling of the screw component, based on raw material type.

2. Using the suitable die head for plastic pelletizing, such as water ring cutting, under-water cutting and hot face cutting.

3. High efficient force feeder ensures stable high capacity material feeding, low power consumption.

4. Main screw has vacuum exhaustion.

5. Water ring granulator machine, attached with dryer. 6. Single screw extruder, with specially designed screw, barrel, venting system, ensure the good quality of the final products.

7. Pelletizing style: standard cutting with extrusion mould. Even cutting ensures with good shape.

PROCESS FLOW:

Conveying feeding → Metal detector → Force feeding → 1# Degassing screw extruder → 1# Hydraulic filer exchanger → 2# screw extruder → 2# Hydraulic filer exchanger → Mould head → Water ring cutting → Dewatering machine → Air dryer Blowing system → Storage hopper → Finished product packing.

PRODUCT PARAMETERS:

| PARAMETERS OF PLASTIC PELLETS MAKING MACHINE | |||||

| Model | MC-85/85 | MC-100/100 | MC-130/130 | MC-160/160 | MC-180/180 |

| Screw Dia. (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-36 | 25-36 | 25-33 | 25-33 | 25-33 |

| Capacity (kg/h) | 120-180 | 200-250 | 400-500 | 450-700 | 500-1000 |

PRODUCT DETAILS:

PICTURE OF THE FINAL PRODUCT: