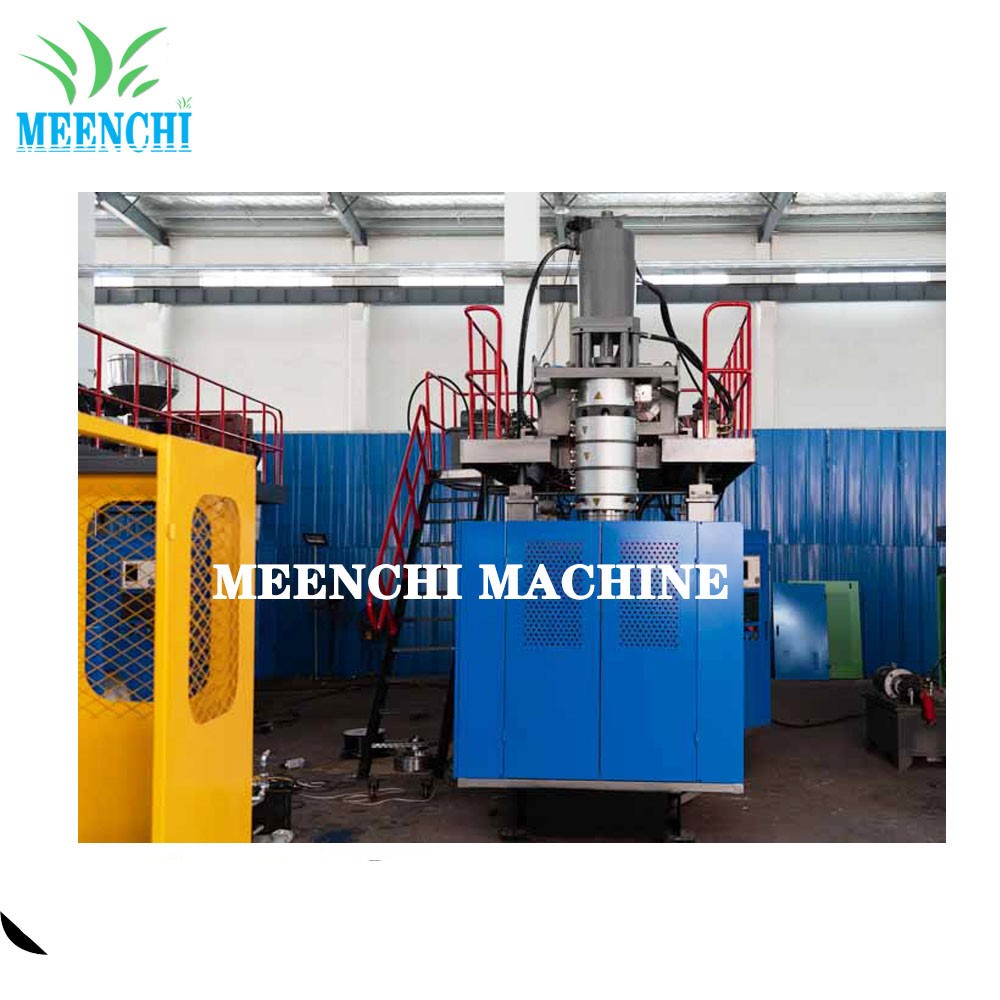

Traffic Road Barrier Blow Moulding Machine

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

This blow molding equipment is a storage type hydraulic full-automatic hollow molding machine, which adopts German technology completely. It can blow hollow containers with the capacity of PE, PP, as and other thermoplastic materials from 100 to 220 liters.

This blow molding machine is fully automatic production, high energy saving, low noise, fast speed, high efficiency, safe and reliable. It is widely used in chemical industry, petroleum, medicine, daily chemical industry, food, lighting, tool, automobile, motorcycle, shoe making, toy and other fields. It is used to blow plastic buckets, chemical buckets, automobile accessories (water tank, oil tank, air-conditioning outlet pipe, automobile tail), toys (wheel, hollow) Motorcycles, basketball stands, children's castles), toolbox bags, duster pipes, stadiums and public car seats, etc. Safe transfer, debugging, training, perfect quality assurance, full service, let you purchase and use at ease.

TRAFFIC ROAD BARRIER BLOW MOULDING MACHINE

PRODUCT DESCRIPTION:

500L Extrusion Blow Molding Machine is accumulating extrusion blow moulding machine for middle and big sized traffic barriers, road blocks, traffic fence, barrier wall and isolation boards. Its output for 2.0m road barrier is 14-15 Pcs, for 1.5m barrier is 16-18 Pcs, for 1.3m barrier is 20-21 Pcs. MC120Z, MC120N & MC100N are the most popular blow molding machines group for traffic barriers, due to strong machine frame, stable working performance, reliable quality, good control to parison length and weight, easy operation and maintenance.

PRODUCT ADVANTAGES:

1. Control system: the operation panel uses 5.7-inch Chinese human-computer interface touch screen, and all actions, parameter setting, monitoring, product counting, wall thickness control and other visual operations. The self judgment of equipment failure shows that the operation is simple. The imported Mitsubishi PLC has the function of process parameter storage and adjustment, quick response, accurate positioning and high stability in operation.

2. Hydraulic system: imported hydraulic valve, seal, electro-hydraulic proportional control. It has the characteristics of stable and reliable, accurate action, long service life and fast response.

3. Extrusion system: adopt hard tooth surface reduction gearbox and Mitsubishi Inverter imported from Japan, with screw frequency conversion speed regulation, low noise, strong power, stable speed, long service life and energy saving features; mix screw, wide adaptability of raw materials, better plasticizing quality, heating barrel and aluminum alloy heater, high efficiency and energy saving.

4. Die head system: adopt central injection storage cylinder die head, horizontal bar injection, high stability. "First in, first out" storage head, reasonable and reliable structure.

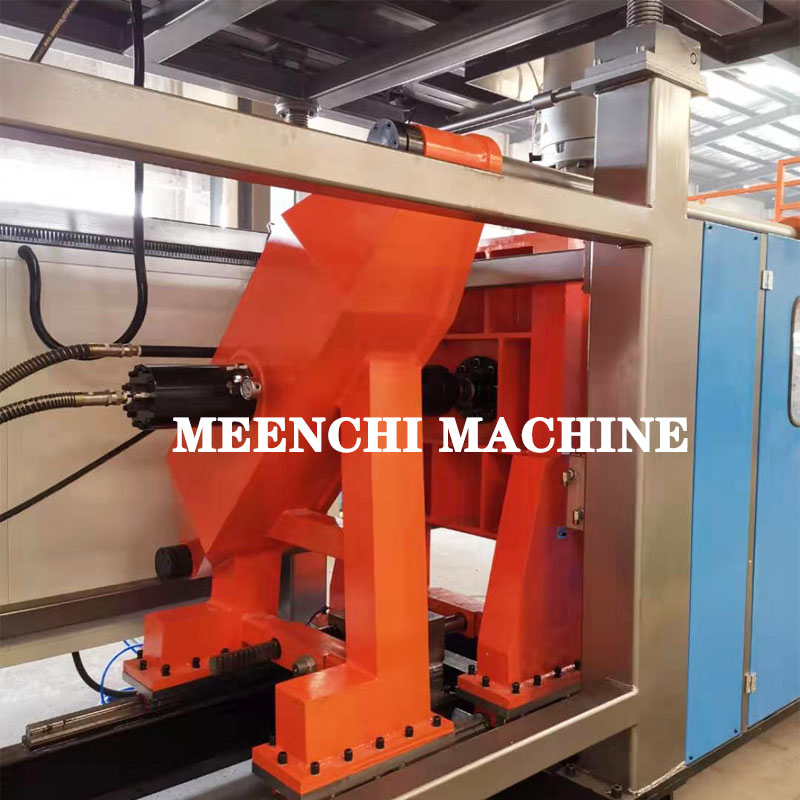

5. Opening and closing die system: pneumatic single cylinder slide rail, fast and stable, four templates, high-precision linear guide rail, hydraulic double cylinder two-way opening and closing die.

6. Model control system: optional Moog in Japan and 10 to 100 point wall thickness control system made in China

7. Air blowing system: it can be selected as standard for down blowing, side blowing and up blowing.

8. Die cutter: standard pneumatic die cutter, fast standard.

9. Safety system: equipped with mold closing protection device and light curtain sensor to ensure the safety of equipment and operators.

10. Electrical components: all of them are international high-tech products.

PRODUCT PARAMETERS:

| SPECIFICATIONS & TECHNICAL DATA | |||||

Extrusion Unit | Screw Diameter | mm | 90 | 110 | 120 |

| Plasticizing Capacity | Kg/hour | 140 | 300 | 380 | |

| Temperature Control Zone | No. | 4 | 5 | 6 | |

Accumulating Head | Accumulating Head Volume | L | 60 | 250 | 500 |

| Total power | Kw | 93.5 | 200 | 240 | |

| Max container capacity | L | 90 | 300 | 500 | |

| Max Die Diameter | mm | 350 | 500 | 600 | |

Clamping Unit | Clamping Force | KN | 350 | 800 | 120 |

| Platen Size | mm | 950*100 | 1200*1400 | 1400*1600 | |

| Opening Distance | mm | 700*1200 | 1000*1600 | 1200*1900 | |

| Screw diameter | mm | 90 | 1200 | 1200 | |

| Max Mould Size | mm | 700*1200 | 1000*1600 | 1200*1900 | |

Driving System | Power of die heating | KW | 21 | 30 | 39 |

| Pump Motor Power | KW | 22 | 30 | 37 | |

| Machine Total Power | KW | 110 | 200 | 244 | |

| Average Power Consumption | KW | 38.8 | 98 | 118.3 | |

PRODUCT DETAILS: