Plastic Toys Blow Moulding Machine

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

Extrusion blow molding machine is a combination of extruder, blow molding machine and die closing mechanism, which consists of extruder and die head, blow expanding device, die closing mechanism, die thickness control system and transmission mechanism. Die head is one of the most important parts to determine the quality of blow molded products. It usually has side feed die head and central feed die head.

The storage cylinder type blank die head is often used in blow molding of large-scale products. The minimum volume of the storage tank is 1kg and the maximum volume is 240kg. The thickness control device is used to control the wall thickness of the blank. The maximum number of control points is 128, generally 20-30. Extrusion blow molding machine can produce hollow products with volume range of 2.5ml-104l.

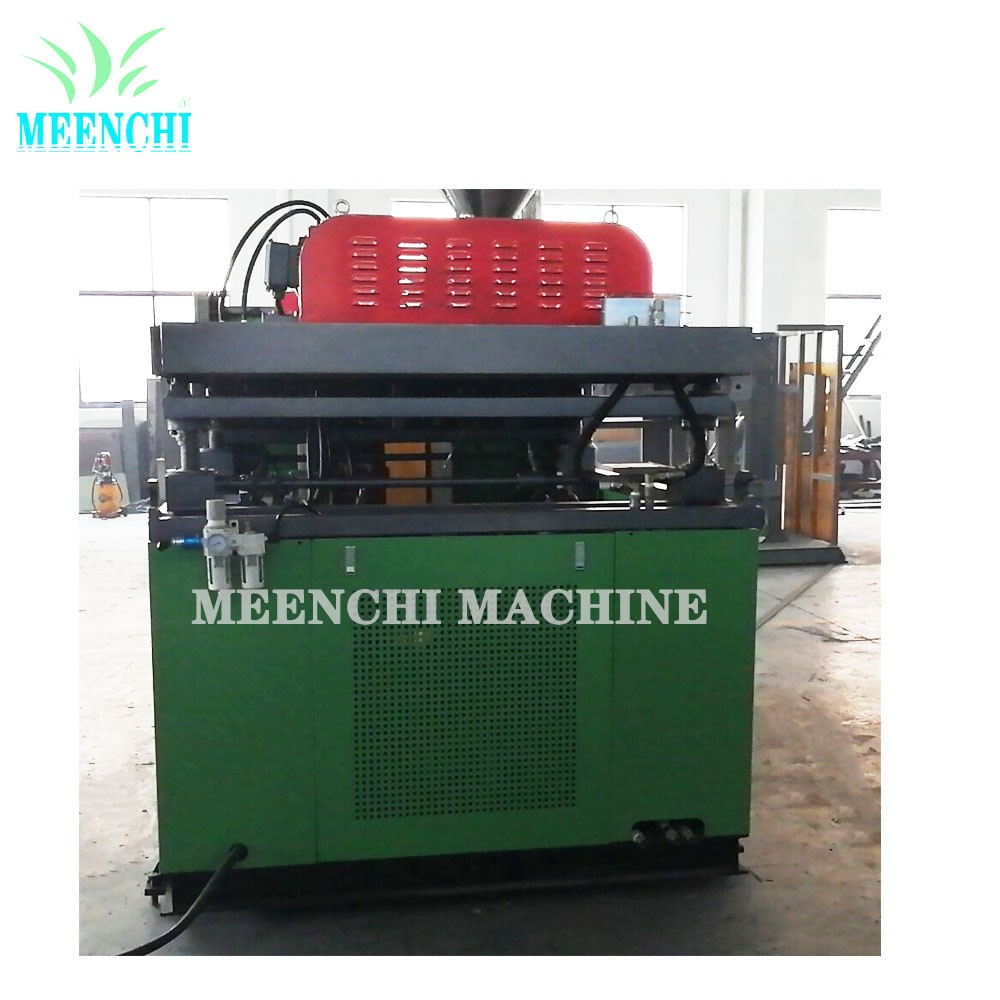

PLASTIC TOYS BLOW MOULDING MACHINE

PRODUCT DESCRIPTION:

Nowadays, plastic products are almost everywhere in people's life. They are no longer simple bottles, films, tires, etc. but more penetrating into high-end products and become irreplaceable materials. Thus also to the plastic product manufacturer has brought the very big development space

Plastic toy children's production equipment / plastic toy blow molding machine / plastic toy equipment fully automatic production, high energy saving, low noise, fast speed, high efficiency, safety and reliability, can also be used to blow oil bottles, bottles, cosmetics bottles, large caliber bottles, hot filling bottles, etc.

Our extrusion and blow molding machines can produce plastic rocking horses, tricycles, small toys, ocean balls, toy stools, chairs, children's tricycle tires, etc.

PRODUCT ADVANTAGES:

1. Speed control system: frequency conversion speed control + hard tooth reducer, stable speed control, energy saving, low noise, durable

2. Plasticizing system: high efficiency plasticizing mixing screw ensures full and even plasticization.

3. Needle blowing frame: integral angle square needle blowing frame, stable and not displaced

4. Electric control system: Mitsubishi PLC computer plus human interface control, color touch screen mode operation, modular temperature control. All process setting functions are realized on the touch screen.

5. Hydraulic system: proportional pressure flow control. Equipped with imported famous hydraulic components, stable and reliable.

6. Configuration of billet control system: imported muger control system is adopted, which can be set with multi-point curve control and precise control.

PRODUCT PARAMETERS:

| Parameter | UNIT | KSC70-10LI | KSC80-10LII |

| Suitable Raw Material | / | PP,PE, EVA,ABS | PP,PE, EVA,PS,ABS |

| Max,Volume of product | L | 10 | 12 |

| Productive capacity | PCS/HR | 100 | 700*2 |

| Die Number | SET | 3 | 4 |

| Clamping force | KN | 90 | 100 |

| platen opening stroke | MM | 190-450 | 190-550 |

| Max mould size | MM | 400-470 | 400-500 |

| Mould thickness | MM | 450 | 500 |

| Heating zone Number | PART | 3 | 4 |

| Die diameter | MM | 150-180 | 160-200 |

| Screw diameter | MM | 70 | 80 |

| Screw L/D ratio | L/D | 1:25 | 1:30 |

| Plasticising Capacity | KG/HR | 80 | 100 |

| Voltage/Frequency | V/HZ | 380V50HZ | 380V50HZ |

| Extrusion machinery motor power | KW | 7.5 | 11 |

| Total power | KW | 39.7 | 59.4 |

| The average energy consumption | KW | 20.5 | 29 |

| weight | TON | 5 | 5.8 |

PRODUCT DETAILS:

Final Production