Plastic Material Hopper Dryer

- Meenchi

- China

- About 40 working days after deposit

- 30 sets per month

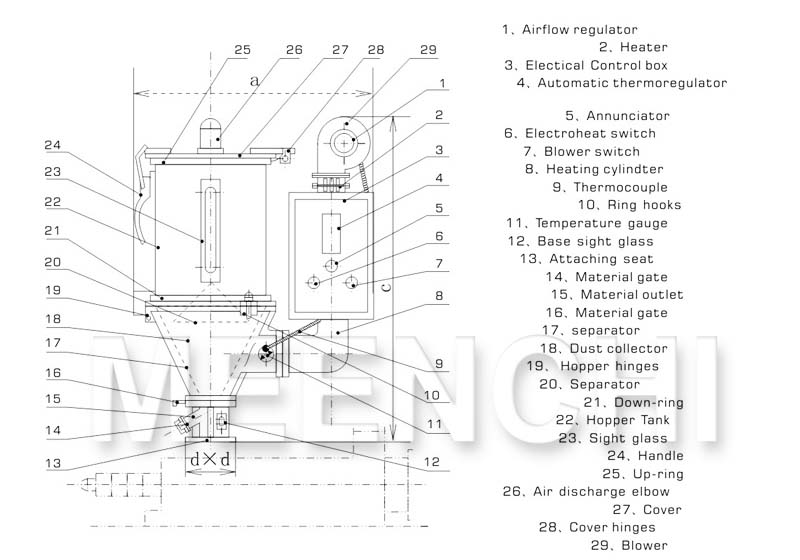

The hopper dryer blows the constant high temperature wind into the drying barrel through the drying fan. After baking the raw materials, the original moisture in the barrel is taken away to remove the moisture contained in the raw materials.

After being heated by electric heating, the air from the fan becomes hot air for drying. Through the screen protector and hole screen, the hot air can be evenly distributed in the raw materials in the drying barrel.

It can be equipped with a hot air recovery device. The blown air enters the drying fan after being filtered by the return air, thus forming a closed circulation circuit and saving electricity.

PLASTIC MATERIAL HOPPER DRYER

PRODUCT DESCRIPTION:

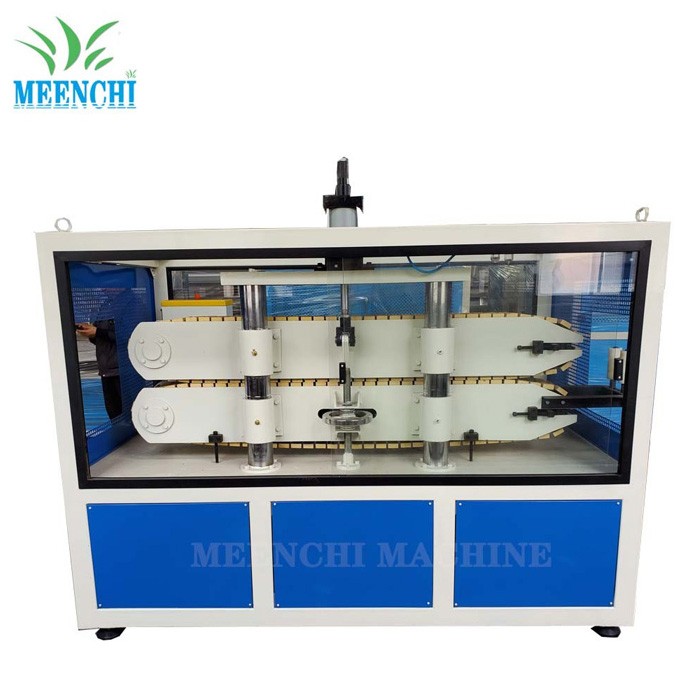

This series of micro pulverizers and ultra micro pulverizers are composed of three parts: main machine, auxiliary machine and electric control. They are compact in design and reasonable in structure. They are of air separation type, no screen and no net.

The machine is equipped with a grading mechanism, which can complete the grinding and grading at one time. The negative pressure transportation makes the heat generated in the chamber continuously discharged during the crushing operation, so it is also suitable for the crushing of heat sensitive materials. The machine has a wide range of applications, and can continuously adjust the size of the discharge material in the production process.

It can handle the crushing and grading of various materials such as chemicals, food, drugs, cosmetics, dyes, resins, shells, etc.

PRODUCT ADVANTAGES:

1. Adopt high performance hot air diffusion device to disperse hot air evenly, keep the drying temperature of plastics even and increase the drying efficiency

2. The special curved design of hot air pipe can avoid the powder from accumulating at the bottom of electric heating and causing combustion

3. All parts in the barrel and inside shall be made of stainless steel

4. The barrel is separated from the bottom, easy to clean and fast to reload

5. It can accurately control the temperature

6. There are double overheat protection devices, which can reduce accidents caused by mechanical failure

7. Various models can provide preheating timing device, microcomputer control, and double-layer insulation barrel for selection

PRODUCT DETAILS: