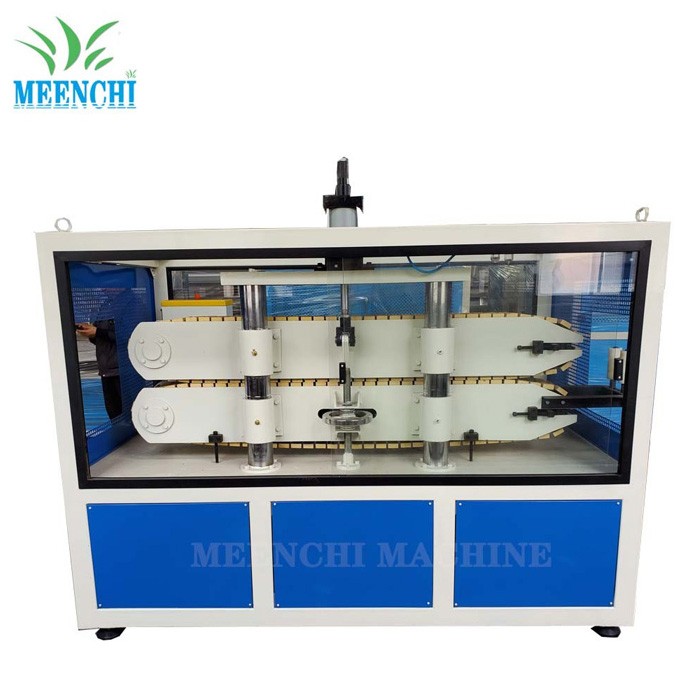

Metal Detector

- Meenchi

- China

- About 40 working days after deposit

- 5 sets per month

As the name implies, metal detector for plastic recycling is an instrument or machine for detecting metal.

In the plastic industry, especially in the recycled plastics, masterbatch, plastic recycling materials, nozzle materials and other industries, there are a variety of metal impurities, such as: copper, iron, aluminum, tin, stainless steel, stainless steel and other magnetic and non-magnetic metal particles. Alert you when there is metal.

METAL DETECTOR

PRODUCT DESCRIPTION:

Zhangjiagang Meenchi Machinery Co., Ltd. is a professional manufacturer of metal detector for plastic, metal detector. The metal detector developed by the company has reached international standards, and is an ideal alternative product of imported metal detector. It is of high quality and low price. Welcome to call from new and old customers.

PRODUCT ADVANTAGES:

1. Adopt imported leading technology and original imported electronic components to greatly improve the stability, sensitivity and anti-interference ability of the product.

2. it has dual signal display function. When a metal object passes through, the signal indicator light will display different induction intensity according to the size of the metal.

3. The signal processing is completed by DSP digital circuit, and the adjustment is simple, stable and reliable.

4. The product is a split type probe with reasonable structure and simple installation. It can be installed without cutting the belt, stopping the machine or affecting normal production.

5. The product detection sensitivity is adjustable from 0-16 level, and it can detect iron metal impurities (such as screws and nuts, staples, nails, blades and other metals) and other non-ferrous metal impurities (such as copper, aluminum, stainless steel, soldering tin and other metals). Prevent harmful metals from entering the crusher, protect the safety of precision and precious equipment, ensure the quality of raw materials and products, and improve production efficiency.

6. Output signal relay output control: when metal impurities are detected, an audible and visual alarm will be generated, and the signal relay will be disconnected to control the conveyor belt of the belt conveyor to stop automatically.