Plastic Chair Blow Moulding Machine

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

This single stage blow molding machine is a storage type hydraulic full-automatic hollow molding machine. It adopts German technology completely. It can blow the hollow container with the capacity of PE, PP, PS, ABS, EVA, as and other thermoplastic materials from 5 to 60 liters.

This extrusion blow moulding machine is fully automatic production, high energy saving, low noise, fast speed, high efficiency, safe and reliable. It is widely used in chemical industry, petroleum, medicine, daily chemical industry, food, lighting, tool, automobile, motorcycle, shoemaking, toy and other fields. It is used to blow plastic buckets, chemical buckets, automobile accessories (water tank, oil tank, air-conditioning outlet pipe, automobile tail), toys (wheel, hollow) Motorcycles, basketball stands, children's castles), toolbox bags, duster pipes, stadiums and public car seats, etc. Safe transfer, debugging, training, perfect quality assurance, full service, let you purchase and use at ease.

PLASTIC CHAIR BLOW MOULDING MACHINE

PRODUCT DESCRIPTION:

This machine can produce bus chair, children's toy chair, outdoor chair, children's safety chair, hospital escort chair, bus stop board chair and other hollow chairs.

We have a strong R & D team, we can develop and produce products according to drawings or samples provided by customers

We have our own foundry and CNC processing plant. So we can directly provide the best price and the best products.

We have an independent design team, professional engineers, to ensure product quality;

Our annual production capacity is more than 500 sets, we can meet the needs of different customers in different purchase quantities.

We focus on developing quality products for high-end markets. Our products meet international standards, mainly exported to South Korea, Southeast Asia, South America, the Middle East, Africa.

PRODUCT ADVANTAGES:

1. Die head: verticality first-in first-out system;

2. Extruder unit: adopt automatic temperature control unit of import,the screw united by hard tooth surface gear box and frequency motorto achieve stepless speed regulation;

3. Clamping device: the clamping device of double draw bar is a type of hydraumatic and fixed , draw bar of new type through template,this type is accommodate large size of mould,smooth action,high stability,clamping mould force is uniformly,template is not distortional;

4. Hydraulic system: whole system adopt imported components,proportional pressure,flow,pressure feedback,system response is faster,action is more smoothly,lowest power loss,and the output of torque is big.

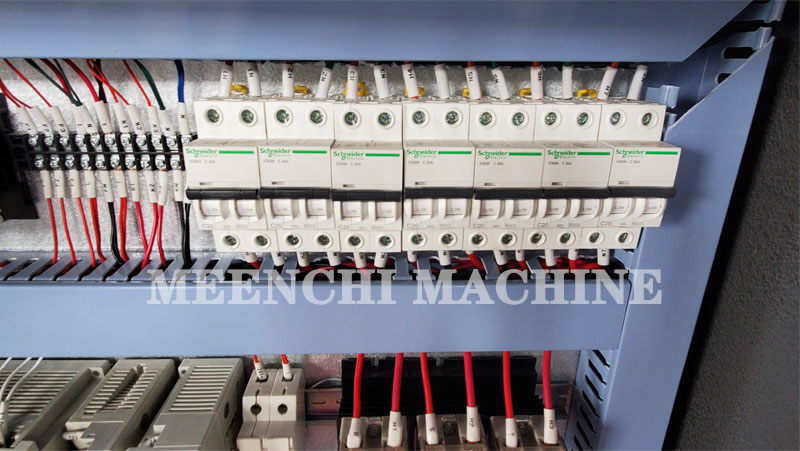

5. Electric controlling system: it adopts Japan programmable controller,touch screen,the characteristic of it has direct manipulation and large information on board.

PRODUCT PARAMETERS:

| Accumulator Die Head Blow Molding Machine for plastic table/chair | ||||

| Specifications | KSA90A-60L | KSA90B-60L | KSB-1000L | |

| Machine Dimebsion | L*W*H | 5.1*2.4*3.8 | 5.4*2.4*3.9 | 7*6*5 |

| Dry Cycle | PCS/HR | 500 | 500 | 1100 |

| Machine weight | TON | 12.8 | 13.5 | 20 |

| Material | PE,PP,ABS | PE,PP,ABS | PE,PP,ABS | |

| Clamping force | KN | 350 | 350 | 1500 |

| Platen Size | W*H | 950*900 | 980*1000 | 2000*2200 |

| Screw diameter | MM | 90 | 90 | 150 |

| Screw L/D ratio | L/D | 25 | 28 | 50 |

| Number of heating zone | ZONE | 4 | 5 | 8 |

| Plasticizing capacity | KG/HR | 140 | 180 | 270 |

| Accumulator capacity | L | 6.6 | 10 | 80 |

| Total power | KW | 93.5 | 114 | 268 |

PRODUCT DETAILS:

schneider electric

Chillers

Final production