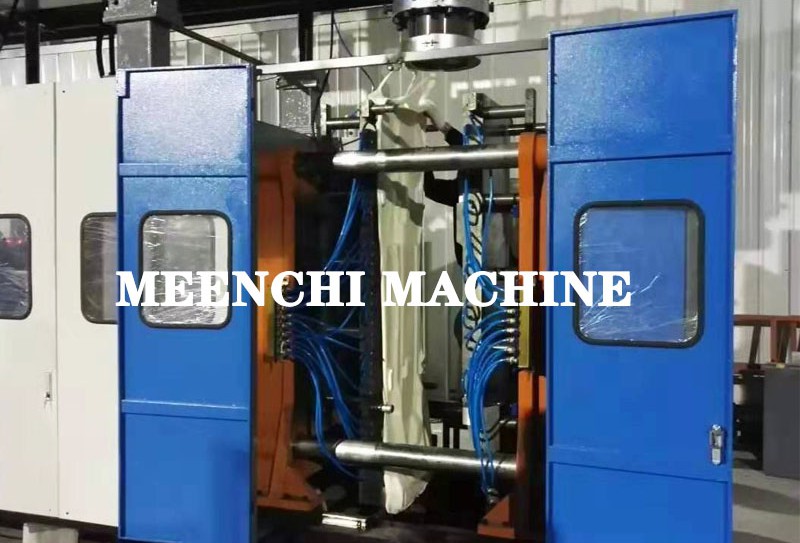

Plastic Board Blow Moulding Machine

- Meenchi

- China

- About 40 working days after deposit

- 10 sets per month

Blow molding desktop production equipment, plastic panel machine, hollow desktop blow molding machine, plastic desktop production line with German technology, professional design, production and sales, with more than ten years of professional design and manufacturing experience.

It has a large number of technicians and technicians with rich practical experience in commissioning and maintenance services for more than 2000 users, and has mature process experience in testing and processing thousands of actual manufacturing. It can produce blow molding machines suitable for processing various special shapes and special raw materials for users.

PLASTIC BOARD BLOW MOULDING MACHINE

PRODUCT DESCRIPTION:

Zhangjiagang Meenchi Machinery Co., Ltd. has more than 20 years of experience in plastic machinery production and R & D, with a high-quality, high skilled production and R & D team. After more than 20 years of development, our products are all over the major provinces and cities of the country, and also sell well overseas.

Our machine can produce all kinds of hollow plastic board, such as medical bed board, transplanter board, outdoor table board, amusement facilities side board, children's fence, massage chair side board, etc.

PRODUCT ADVANTAGES:

1. Reasonable structure design and solid frame manufacturing to insure running stability.

2. Good head material runner deisgn and precision metal process for changing color easily.

3. According to your specified request, our machine can be made with co-extrusion of 1~3 layers and view stripe line.

4. Colorful touch screen, cantilever operation box, energy saving servo motor, robot arm and safety protection.

5. Total machine control system well match with pushing-out, core in/out, sub-mould de-molding, angle adjustable blowing unit, neck trimming tool, in-mould labeling, weight testing and leakage testing, product conveying & packing.

PRODUCT PARAMETERS:

| Product specification | ||

| Model | KSC120-60LII | KSA70-10L |

| Machine dimension(LxWxH) | 6.2*3.9*3.6 | 3.2*1.4*2.7 |

| Machine weight | 28ton | 5.2ton |

| Total power | 168.5kw | 41kw |

| Average power consumption | 92.4kw | 23kw |

| Max. shot weight | 45kg | 30kg |

| Heating power | 24kw | 14.2kw |

| die diameter | 350mm | 180mm |

| Screw diameter | 120mm | 70mm |

| Screw L/D ratio | 30 | 24 |

| Extruder motor power | 110/110kw | 110/110kw |

| Plasticizing capacity | 350kg/h | 80kg/h |

| Clamping platen size | 900-950mm | 520-580mm |

PRODUCT DETAILS:

PHOTO OF PRODUCTION: